Hiroaki Ohtani

Post By:Kitticoon Poopong

Starting with a tiny lot in Kobe, Japan, Hiroaki Ohtani turns rough, stacked concrete beams into the striped and shadowy Layer House

Photo © Kouji Okamoto / Technistaff

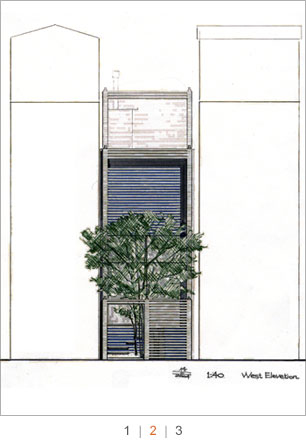

In Japan, people have a predilection for white: white rice, white cars, white houses. But Hiroaki Ohtani, the owner and architect of Layer House, is no Japanese everyman. On a site near the center of Kobe, he built a shadowy dwelling of stacked, rough, concrete beams reminiscent of railroad ties. Apart from its largely plate-glass front facade, Layer House has no windows or conventional doors and no trace of white except for the bathtub—and that’s a French import.

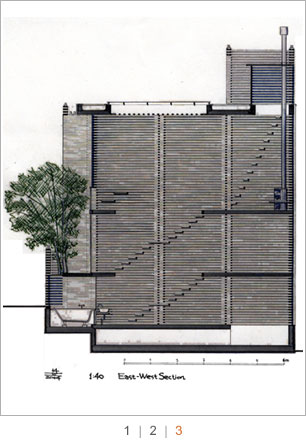

While a gatelike, concrete frame draws an invisible line between public and private realms, the mostly glass facade (with a sliding panel for passage in and out) reveals the 822-square-foot house’s inner workings. But the architect preserved a modicum of privacy by placing floors only above and below—not at—street level. A study (the daughter’s future bedroom) and the sole bathroom occupy the lowest story, rising to the entrance and bedroom on the middle floor and finally, at the top, the kitchen and living room. Washed in muted rays from a skylight above, the uppermost level offers the brightest spot in the house.

By contrast with the front facade’s relationship to the site line, the opaque side and rear walls stand as close to the adjacent houses as possible, making the most of the site’s 9.5-foot width. The exterior walls—a curious blend of traditional know-how and contemporary technology—consist of horizontal layers (hence the name Layer House) of precast-concrete bars reinforced with prestressed steel wires and pinned in place by thick steel rods. The bars range proportionately from 3.6 meters to 36 centimeters (118 feet to 15 inches) in length, with longer members for outer walls and shorter ones for the interior. All of these factory-molded components had to be carried on-site and installed by hand—a painstaking process that took 13 months.

As important as the solids, the voids are what make this concrete shell a habitable home. Throughout the building, the architect fitted out the slots with plug-in furnishings—ash wood shelves, desk slabs, and skinny drawers, along with towel hangers, clothing rods, and light fixtures—that the occupants can rearrange at will.

the People Architect Hiroaki Ohtani, JIA Himoyamate-dori 4-11-4 Chuo-ku, Kobe 650-0011, Japan Hiroaki Ohtani, JIA General contractor Marukoh Kensetsu Co., Ltd. | the Products Structural System / Exterior Cladding Façade: PCaPC (Precast pre-stressed concrete) slats compression joint method; manufacturer: P.S. Mitsubishi Construction Co., Ltd. www.psmic.co.jp External walls at both sides: Iso-Wand (Thermal insulating material sandwitched with galvalium steel panels); manufacturer: Nittetsu Steel Sheet Corporation www.nittetsu-kouhan.co.jp Windows Stainless steel window frame Bathtub & wash basin: CERA Faucets: Dornbracht www.dornbracht.com Kitchen Appliances Refrigerator: AEG www.aeg.co.uk Stove: Gaggenau www.gaggenau.com Wood-burning stove: RAIS www.rais.co.uk |

via:archrecord--