Robert Harvey Oshatz Architect

Photo © Cameron R. Neilson

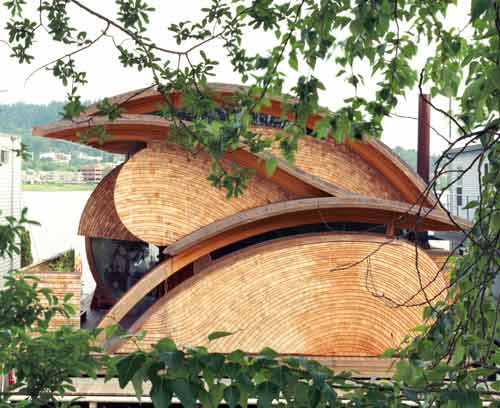

There’s something so romantic about living waterside. Waking up to a dramatic view, whether from the banks of a lake, ocean, river, or even a tiny brook, always seems to have a soothing effect on the soul. One way to amp up the romance is to take the dwelling off the shore and put it right onto the water, as Portland, Oregon-based architect Robert Oshatz did for his clients. The professional couple, which spends most of their time in downtown Portland, had purchased a mooring on the east side of the Willamette River, an active commercial and recreational body of water. They turned to Oshatz, known for his curvaceous, swooping architecture, to create a floating house as their weekend and summer retreat.

Photo © Cameron R. Neilson

The couple was familiar with Oshatz’s work, so they knew their house would be one of a kind. “People often get the idea that the forms come first with me,” says Oshatz. “But that’s the opposite of how I work. For any project I do, my main goal is to take the client exactly where they want to go. We start with the site, create the floor plan, and go from there.” For this house, in addition to addressing the programmatic requirements, Oshatz had the challenge of building a house that was sturdy yet able to float, and he had to deal with the fact that active construction on the Willamette is prohibited (the home had to be built on the connected Columbia River, then pulled by barge to its mooring on the Willamette). Also, moorings on either side were less than 10 feet away—the house had to provide privacy despite the close proximity to neighbors.

Photo © Cameron R. Neilson

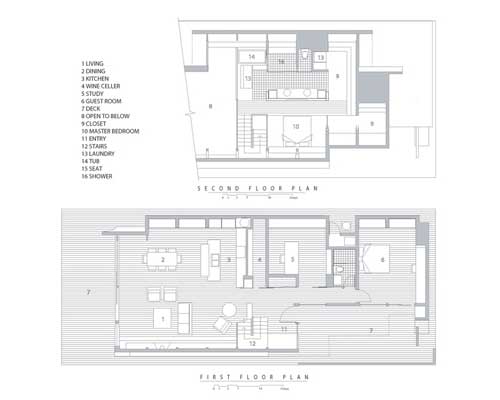

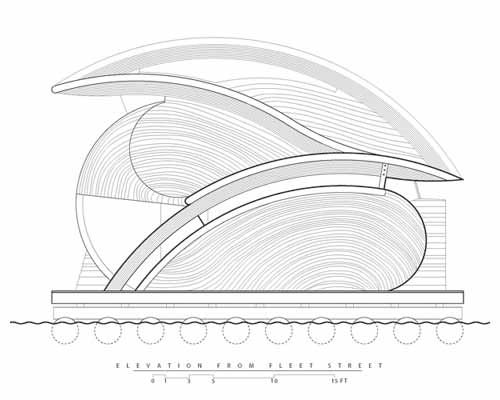

The clients are fans of loft-style living, and needed no more than a master bedroom, a study, guest bed and bath, and kitchen and living areas. With the floor plan and program in place, Oshatz found inspiration in the ripples of the river, and used Douglas fir glulam beams to form the house’s curving arcs. Cedar shingles clad the eastern, northern, and southern exposures, while the western side opens up to the river with floor-to-ceiling glass sliding doors with curved glass windows above. “For this house I created one curving radius for the full home, then manipulated an s-curve to fit inside that radius,” says Oshatz. The resulting interior gives the feeling of being inside a seashell. The kitchen, open living room with fireplace, and guest bedroom are all on the “ground” floor, with a stairway leading up to the master-bedroom loft space. Built-in cabinets and storage elements (of American cherry) keep furniture to a minimum, while Brazilian cherry floors and stairs contribute to the house’s warm atmosphere. The deck is mahogany, while the roof and ceiling beams are Douglas fir. Stainless-steel stair railings contrast with the wood inside, while copper shingles provide the contrast on curved, vaulted areas on the exterior.

Photo © Cameron R. Neilson

For Oshatz, creating a home that floats was just one of the project’s challenges. “The clients had been led by friends to several architects in Portland who built very rectilinear modernist homes, but that wasn’t what they wanted,” says Oshatz. “Still, they came to me and said they wanted the house finished within a year. I told them it could not happen that quickly, and we almost parted ways. I had a house under construction and I offered to have them come take a look at it, which they did, and it gave them a way to visually understand the difficult process of building a home. They came back to me with that understanding, and we began design. The house actually took five years from design to completion.”

Photo © Cameron R. Neilson

To make the house buoyant yet stable, Oshatz created a 34 by 80-foot float made up of Douglas fir logs. Steel I-beams were then placed crosswise, set 6.5 feet on center, because that was the spacing Oshatz decided on for the curved glulam beams. “To simplify the float I wanted the load of each curved glued laminated beam to come directly down on each I-beam,” says Oshatz. “Three-and-a-half by 5.5-inch pressure treated plates were placed across the I-beams at 4 feet on center, then floor joists run across the pressure-treated plates (11.2-inch TJI’s at 32 inches on center).” As Oshatz explains, insulation, plumbing, and ductwork were installed before the 1.125-inch plywood sub flooring was laid, and 4 by 4 foot cubes of rigid foam were placed under the logs to keep the float level and the I-beams about 6 inches above the water line. As more weight was added to the float during construction, more cubes were added. “It was really quite simple,” says Oshatz, “and now that I know how it’s done I’ll probably never have the chance to build such a house again!”

Photo © Cameron R. Neilson

But all experiences are worth having, and Oshatz says he’s lucky enough to be able to visit the house often. “Going through such an intense process of building a home for someone, I often become friends with my clients,” he says. “And these clients’ river view is so beautiful that I’ll go over there whenever I’m invited. It’s a house that went from emotional thought to logical conclusion and, like all the homes I design, I think it’s a structure that’s at peace with itself and its surroundings.”

Photo © Cameron R. Neilson

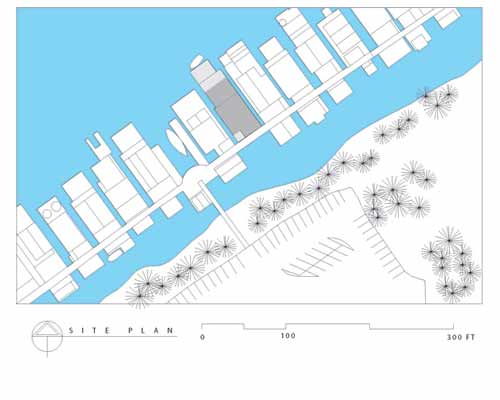

Site plan

plan

Elevation

Gross square footage:

2,364 sq. ft.

the People Owners Randall T. Fennell Architect's firm name Personnel in architect's firm who should receive special creditRobert Harvey Oshatz, Architect PO Box 19091 Portland, Oregon 97280 503-635-4243 robert@oshatz.com www.oshatz.com Robert Oshatz, Architect Architect of record Robert Harvey Oshatz Interior designer: Robert Oshatz Engineer(s) Structural EngineerTKSE Brett King 10101 SW Barbur Blvd., Suite 208 Portland, Oregon 97219 503-242-4990 brett@tkse.com General contractor: Even Construction Marc Even 9900 SW Sattler St. Tigard, Oregon 97224 503-806-4795 marc@evenconstruction.com www.evenconstruction.com Photographer The seenCameron R Neilson; photographer PO Box 8485 Jackson, WY 83002-8485 307-734-9775 cameron@theseenphoto.com www.theseenphoto.com | the Products Structural systemDouglas Fir glued laminated beams and columns with 2x6 Douglas Fir T & G decking Glued laminated beams and columns by: Calvert Company, Inc. randy@calvertglulam.com Exterior cladding Metal:Copper shingles Wood: Western Red Cedar shingles Roofing Metal:Copper Windows Wood: Loewen www.loewen.com/ Glazing Glass:General Glass www.generalglass.com Insulated-panel or plastic glazing: General Glass www.generalglass.com Doors Wood doors:Willow Classic Woodworking 107 SE Washington St. Portland, OR 97214 Sliding doors: Willow Classic Woodworking 107 SE Washington St. Portland, OR 97214 Siding glass wall doors: The Glass Guru, Portland , Oregon www.theglassguru.com Interior finishes Cabinetwork and custom woodwork:American Cherry Special surfacing: Floor and wall tile: Granite tiles in bathrooms Flooring: Brazilian Cherry Plumbing American Standardwww.americanstandard-us.com |